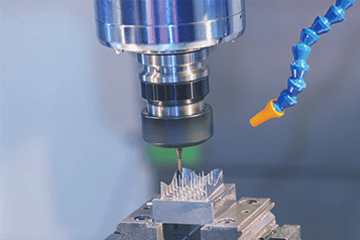

A CNC (Computer Numerical Control) system runs on a PC program; it could both be for prototyping or incomplete element introduction. Aluminum is the typically machined cloth, because it indicates notable machinability, and is, therefore, the popular cloth withinside the maximum assembling area.

Aluminum as a cloth gives a few interesting heat and mechanical residences. Moreover, aluminum steel is really easy to form, in particular in dull cycles, as in cnc aluminum manufacturing. Indeed, we particularly appreciate an aluminum compound contrasted with different light-weight metals, for example, magnesium and titanium amalgams.

The usage of CNC aluminum has evolved monstrously, the introduction of CNC vehicle mobile components and different CNC components which are lightweight has been extreme. The following are multiple belongings you may not have known.

Aluminum Material:

Aluminum is delicate, light-weight, manageable, moldable, and stable steel. Its look is silver or stupid darkish and is based upon the unpleasantness of the surface. It desires appealing residences and is non-combustible. The aluminum steel melts at 640 degrees, and it is mild with a thickness of 2.68. It is a first-rate conveyor of energy but is now no longer of a comparable norm as copper on specific cross-section vicinity and is normally applied in CNC vehicle mobile like ATV, Aerospace, and medical enterprises.

Aluminum Grade

A definitive selection of the type of aluminum grade you assume to make use of is based upon your machining projects, which allow you to rank every grade as indicated via way of means of its trademark, from the maximum critical to the least. Thusly, you get to choose the aluminum of specific residences and form in keeping with your requirements.

Coming up subsequent are some types with essential realities approximately Aluminum grade;

Aluminum 6061: This grade has chic mechanical residences, exquisite weldability. Its powerful residences make it one of the maximum expelled grades. This is a result of its notable sturdiness, medium and excessive strength, notable erosion obstruction on unforgiving conditions, cool anodization, and twisting usefulness. Aluminum 6061 is often applied for five hub CNC machining.

Aluminum 7075: It’s moreover widely recognized despite the truth dislike the 6061. This grade is thought for its wonderful exhaustion strength. This aluminum grade isn’t always affordable for welding; it is exorbitant. Thus, it’s far higher for excessive components, for example, fuselages, motorcycle components, mountain climbing units, and aircraft wings. This aggregate is likewise higher in erosion obstruction.

Aluminum 2024: The amalgam is prevalently applied in the army and aviation area. This is a result of its mechanical residences, just like wonderful exhaustion competition, and excessive strength. The aluminum 2024 is horrendous in erosion competition and is now no longer weldable.

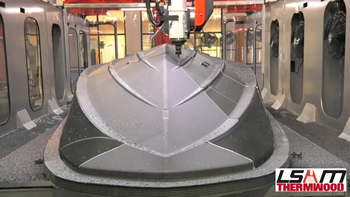

CNC Aluminum Prototype

Aluminum machined versions are typically created via way of means of a collection of composites. The maximum applied aggregate is the 6061-T6, these chefs for gadgets, transportation, aviation, army ventures amongst others.

Aluminum combos are low in thickness but excessive in strength. Regularly CNC aluminum version machining has the huge resilience to govern even 0.01MM. The CNC system can produce top-notch and great aluminum models. CNC processing is best the perfect selection, the blessings are with the machining system, and this is the excessive accuracy and processing aluminum.