Ventilatoare pentru medii corozive play a critical role in keeping corrosive environments safe. Whether it’s a factory, chemical plant, or waste water treatment center, ventilators protect the people within it by providing clean, safe air while they work.

Why Ventilators Are Needed in Corrosive Environments

Corrosive materials such as chemicals, acids and alkalis can cause discomfort and long-term health problems. These hazardous substances produce fumes that, when inhaled, can result in serious respiratory illnesses. In addition, certain chemicals create vapors that are highly flammable, potentially causing explosions and fires. Without proper ventilation, these hazardous substances can quickly reach dangerous levels, endangering both people and property.

The Benefits of Industrial Ventilators

Industrial ventilators provide a number of benefits for businesses operating in corrosive environments. Not only do they reduce the risk of exposure to hazardous fumes and gases, but they also help regulate air pressure levels, promote air circulation, dissipate excess heat, and improve overall air quality. From avoiding potential accidents to increasing staff comfort, having an industrial ventilator in place can have a positive impact on any workplace.

Types of Industrial Ventilators

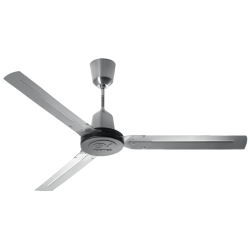

Industrial ventilators come in a variety of shapes and sizes, depending on the needs of the business. Common types of ventilators include axial fans, centrifugal blowers, and electrostatic precipitators. Axial fans use propellers to move air, while centrifugal blowers force air through a pipe or duct using a fan wheel. Electrostatic precipitators use an electrical charge to remove particles from the air. Each type of ventilator has its own advantages, so be sure to consult with a professional to determine which one is best for your particular application.

Common Applications for Industrial Ventilators

Industrial ventilators are used in a number of different applications. They are often used to cool engines and power tools, ventilate kitchens, provide fresh air to workers in confined spaces, eliminate odors, and exhaust hazardous fumes. Industrial ventilators can even be used to heat warehouses and manufacturing plants, providing a cost-effective way to keep employees comfortable during colder months.

Maintenance and Safety Tips

Despite their effectiveness, ventilators must be properly maintained to ensure optimal performance. The filters should be cleaned or replaced regularly to prevent clogging and blockage, and all electrical components should be inspected for signs of damage. Be sure to follow all safety procedures when working with industrial ventilators, and make sure that all staff members are properly trained on the proper usage and maintenance of the equipment.

Finding the Right Ventilator

With so many different types of industrial ventilators available, it’s important to choose the right one for your needs. Consider factors such as size, capacity, and intended use before making a purchase. If you’re unsure, seek the advice of a professional to help you make an informed decision.

Ventilatoare pentru medii corozive are an essential part of keeping workplaces safe in corrosive environments. Not only do they reduce the risk of exposure to hazardous fumes and gases, but they can also improve air quality, increase employee comfort, and reduce energy costs. When choosing an industrial ventilator, remember to consider its size, capacity, and intended use before making a purchase.